Laser Cutter

The Laser Cutter is located in Washburn, and is available for use whenever a lab monitor is on duty. Please read the lab policies and guidelines on the manufacturing labs my.wpi.edu site.

Contents

Approved Materials for Laser Cutter

- Acrylic

- Wood and paper based materials such as birch, balsa, or vanilla folder, and hard or soft wood excluding laminated woods. (For example, Plywood is not allowed)

- Cloth

The table size for the cutter is 18" x 24" and can cut the approved materials up to 3/8", but 1/4" or less is recommended for accurate and timely cuts.

Reserving the Laser Cutter

Reserving the laser cutter gives you priority to use the machine. If you are more than 15 min late to a reservation you forfeit your reservation. It is frowned upon to reserve the laser cutter for more than 2 hours at a time.

Steps to becoming a laser cutter master:

1. Go to http://www.wpihtec.org (login using your WPI username and password) and click “Before Working in the Lab”

2. Scroll over “Information for Students” at the top of the page and click “Become a Lab User”

3. Read the “General Policies”

4. Complete “Safety quiz” and wait for confirmation that you passed

a. You should wait for email conformation

5. Return to http://www.wpihtec.org and click “Register a New Project”

6. Fill in all the required information regarding the course and project description(this can be brief).

a. Name your project with class name and group # to make it clear what the purpose is.

b.You should wait once again for email conformation.

7. Return to http://www.wpihtec.org and click “Machine Tool Schedule”

8. Scroll over desired time slot and click “+Add”.

9. Fill in all of the required information

a. Operator: name of student certified in the lab safety

b. Machine Tool To Schedule: laser Cutter click Add>

c. Purpose: final project

d. Project: scroll and click on the project you registered

e. adjust desired time

f. Await email conformation

10. ***Remember that you must arrive within the first 15 min of the reserved time other wise you will forfeit the machine tool reservation

11. ***You also need to make reservations at least 3 hours before the desired reservation time.

12. Once in lab

a. At the door you must call into the lab monitor and report your reason for coming in

“I’m here for my laser cutting reservation at (blank time) for RBE (course)”

b. Once inside put on a pair of safety goggles

c. The laser cutter is right on the left when you enter the lab

d. Next to the computer is a step by step manual to assist with actually using the machine

(you can also find it if you return to http://www.wpihtec.org and click “Laser Cutter Manual”). A lab monitor should also be around to assist with additional questions.

Now you are a Laser Cutter Master. Go make cool things!! 😊

Laser Cutter Manual

Complete instructions for using the laser cutter.

File:WPI Laser Cutter Guide RB.pdf

Cutting Material Suppliers

MSC has acrylic and delrin available in many thicknesses, colors, and sizes. They provide free ground shipping that is normally delivered the next work day if the order is placed before 5pm.

PSI also has a wide variety of plastics in stock as well as fabrication and other related services. They are located in Manchester, NH and usually turn around orders very quickly.

Home Depot usually stocks sheets of acrylic although they tend to be larger than you may want. But sharing a sheet with other groups is always an option.

Lowe's also stocks sheets of acrylic. The sheets described on their web site tend to be somewhat smaller in size than those found on the Home Depot web site.

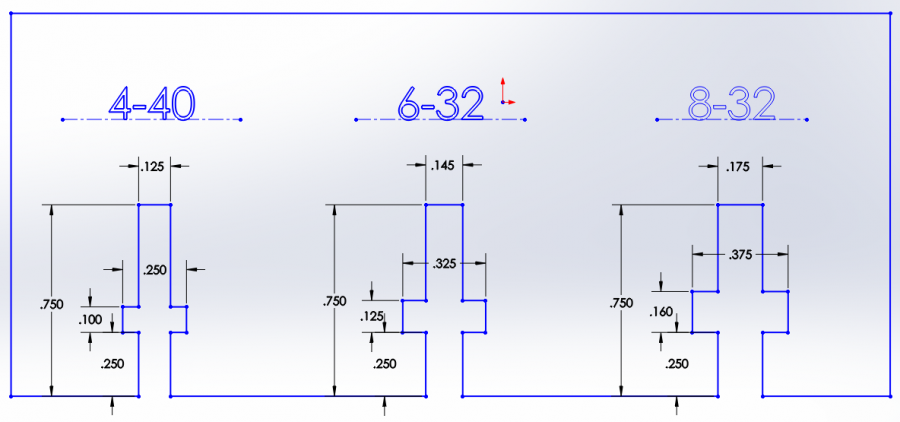

Screw Hole Template

This is a template for screw holes used to join pieces of acrylic to each other or other VEX parts using screws and nuts available in the lab. All measurements are in inches.

Recreate the shape and measurements for your screw size of choice. Only change the height dimension (here, 0.750in).

The 0.25" between the bottom and the space for the nut is necessary so the acrylic doesn't crack. Do not make this dimension any smaller.

6-32 is a VEX motor screw, and 8-32 is a VEX standard screw.